Introduction: Miscanthus as a High-Potential Energy Crop

Miscanthus is widely recognized as one of the most promising perennial energy grasses in the biomass industry. Thanks to its fast growth, high yield, and low cultivation requirements, miscanthus has become a preferred raw material for renewable energy projects in Europe, North America, and parts of Asia.

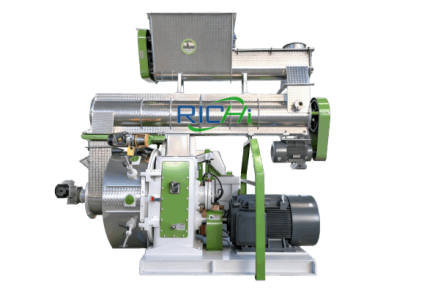

However, raw miscanthus grass has low bulk density and high transportation costs. Converting it into pellets using a professional miscanthus pellet mill significantly improves handling efficiency, energy density, and commercial value. This makes pelletizing an essential step for large-scale biomass utilization.

Characteristics of Miscanthus for Pelletizing

Compared with traditional agricultural residues, miscanthus offers several advantages as a pellet raw material:

- High fiber content, suitable for pellet bonding

- Stable supply from dedicated plantations

- Lower ash content than many crop residues

- Consistent chemical composition

At the same time, miscanthus stalks are tough and fibrous, which places higher demands on crushing, conditioning, and compression stages. Without proper equipment matching, pellet quality and production efficiency may be affected.

This is why specialized pelletizing solutions are critical for long-term, stable operation.

(Related Post: https://biomasspelletizer.com/miscanthus-pellet-mill/)

Role of a Miscanthus Pellet Mill in Biomass Processing

A professional miscanthus pellet mill is designed to process fibrous grass materials under high pressure and temperature. Unlike feed-oriented machines, biomass pellet mills focus on durability, energy efficiency, and continuous output.

Key benefits include:

- Enhanced compression for tough grass fibers

- Uniform pellet diameter and smooth surface

- Reduced fines generation during production

- Compatibility with industrial-scale operations

In many projects, the pellet mill works as the core unit of the entire system, determining final pellet density, strength, and combustion performance.

Complete Grass Pellet Production Line Equipment Overview

For commercial production, a single pellet machine is not enough. A full solution requires complete grass pellet production line equipment that integrates multiple processing stages into one coordinated system.

1. Size Reduction and Crushing

Miscanthus stalks are first chopped and crushed into uniform particles to improve pelletizing efficiency and reduce wear on downstream equipment.

2. Drying and Moisture Control

Moisture content is adjusted to an optimal range to ensure strong pellet bonding and prevent cracking during cooling.

3. Pelletizing with High-Pressure Compression

The prepared material enters the pelletizing section, where heat and pressure activate natural lignin, forming dense biomass pellets.

4. Cooling, Screening, and Packaging

Fresh pellets are cooled to increase hardness, screened to remove fines, and prepared for storage or transportation.

This integrated approach helps operators maintain stable output and predictable pellet quality.

Applications in a Modern Biomass Pellet Industry

Miscanthus pellets are widely used in industrial and commercial energy applications. In a modern pellet production facility, they serve as:

- Fuel for biomass boilers and heating plants

- Co-firing material in coal-fired power stations

- Renewable energy feedstock for export markets

- Sustainable fuel for agricultural and industrial users

With proper system design, investors can scale production efficiently and adapt to local market demand. To better understand system configuration options and capacity planning, you can use this link to explore additional technical references and solution examples.

Pellet Press Selection and System Compatibility

The pellet press plays a decisive role in determining pellet density and durability. Selecting the right die specification, compression ratio, and motor power ensures stable operation when processing fibrous grass materials like miscanthus.

A well-matched pellet press not only improves pellet quality but also reduces maintenance frequency and operating costs. When combined with proper pre-treatment and cooling systems, it supports long-term, continuous production.

Conclusion: Building a Sustainable Miscanthus Pellet Project

As global demand for renewable energy continues to grow, miscanthus stands out as a reliable and scalable biomass resource. By adopting a high-performance miscanthus pellet mill and an integrated grass pellet production system, producers can convert raw grass into high-value biomass fuel efficiently.

With the right equipment selection and system planning, miscanthus pellet production offers strong economic potential and long-term sustainability for biomass investors worldwide.